G7622 Trackside Communications Cables

Applications :

- The cables are designed for installation in trackside bracket runs and for use within railway equipment rooms within open locations (type 1) or in subsurface tunnels and underground locations (type 2).

Standards :

- LUL Spec G7622 A1 type 1 (for PVC sheath)

- LUL Spec G7622 A1 type 2 (for LSZH sheath)

|

|

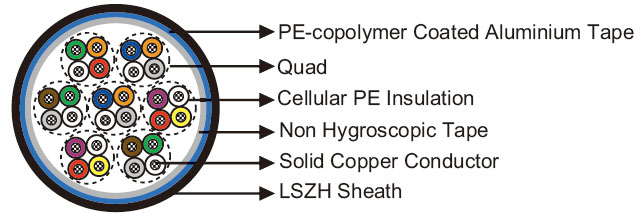

Construction :

- Conductors : Solid plain copper, 0.63/0.9 mm nominal diameter.

- Insulation : Cellular polyethylene.

- Cabling Element : Four insulated conductors are twisted together to form a quad.

- Stranding : Conductors are helically stranded in concentric layers.

- Core Wrapping : Plastic tape (s) with overlapping.

- Moisture Barrier : One laminated sheath made of aluminium tape (0.15mm thick) coated with PE-Copolymer on at least one side is applied with longitudinally overlap.

- Outer Sheath : LSZH sheath, coloured violet.

Optional :

- Type 1 Cables : For type 1 cables, additional foil (at least one polyester tape) and PVC sheath are applied over the LSZH sheath. (VDE Code: A-02Y(L)HY).

- Armoured Cables : Corrugated steel tape armour is applied with an overlap over LSZH sheath. An outer LSZH sheath is applied over the armour. (VDE Code: A-02Y(L)H(SR)H).

Electrical Characteristics at 20 °C :

-

Nominal Conductor Diameter mm 0.63 0.9 Maximum Conductor Resistance Average Value Ω/km 57.5 28 Individual Value Ω/km 59 29 Minimum Insulation Resistance @500 V DC MΩ.km 1500 1500 Maximum Average Mutual Capacitance nF/km 59 59 Maximum Average Capacitance Unbalance Between pairs in same quad pF/460m 50 50 Between pairs (centre or in any layer) pF/460m 30 30 Between any pairs and earth pF/460m 200 200 Between phantom and pairs in same quad pF/460m 300 300

Mechanical and Thermal Properties :

- Minimum Bending Radius : 7.5×OD (unarmoured); 10×OD (armoured).

- Temperature Range : -40°C to +70°C (during operation); -10°C +50°C (during installation).

Core Identification :

Quad colours in centre and even layers

| Position of Quad in Layer | Centre and Even Layers | Quad Whipping Colours | |||

| A Wire | B Wire | C Wire | D Wire | ||

| 1st Quad (Marker) | ORANGE | WHITE | BLUE | GREY | WHITE/ORANGE |

| Even Quads | RED | WHITE | VIOLET | YELLOW | WHITE |

| Odd Quads | BROWN | WHITE | GREEN | GREY | WHITE |

| Last Quad | ORANGE | WHITE | RED | GREEN | WHITE/ORANGE |

Quad colours in odd layers

| Position of Quad in Layer | Centre and Even Layers | Quad Whipping Colours | |||

| A Wire | B Wire | C Wire | D Wire | ||

| 1st Quad (Marker) | ORANGE | BLACK | BLUE | GREY | WHITE/ORANGE |

| Even Quads | RED | BLACK | VIOLET | YELLOW | WHITE |

| Odd Quads | BROWN | BLACK | GREEN | GREY | WHITE |

| Last Quad | ORANGE | BLACK | RED | GREEN | WHITE/ORANGE |

Make-up of cable

| Number of Pairs | Number of Quads in centre and successive layers | ||||||

| Centre | 1st Layer | 2ndLayer | 3th Layer | 4th Layer | 5th Layer | 6th Layer | |

| 8 | 4 | - | - | - | - | - | - |

| 14 | 1 | 6 | - | - | - | - | - |

| 20 | 2 | 8 | - | - | - | - | - |

| 28 | 4 | 10 | - | - | - | - | - |

| 38 | 1 | 6 | 12 | - | - | - | - |

| 54 | 3 | 9 | 15 | - | - | - | - |

| 74 | 1 | 6 | 12 | 18 | - | - | - |

| 104 | 4 | 10 | 16 | 22 | - | - | - |

| 160 | 4 | 10 | 16 | 22 | 28 | - | - |

| 228 | 4 | 10 | 16 | 22 | 28 | 34 | - |

| 308 | 4 | 10 | 16 | 22 | 28 | 34 | 40 |

Dimensions and Weight :

G7622 A1 Type 2 Cables

| Cable Code | No. of pairs | Minimum Sheath Thickness mm |

Nominal Overall Diameter mm |

Nominal Weight kg/km |

| 0.63mm Conductor, 1.0mm Insulated Wire | ||||

| RS7622A1/T2-02Y(L)H-8P0.63 | 8 | 2.5 | 14.5 | 190 |

| RS7622A1/T2-02Y(L)H-14P0.63 | 14 | 2.5 | 16.0 | 240 |

| RS7622A1/T2-02Y(L)H-20P0.63 | 20 | 2.5 | 17.5 | 310 |

| RS7622A1/T2-02Y(L)H-28P0.63 | 28 | 2.5 | 19.5 | 380 |

| RS7622A1/T2-02Y(L)H-38P0.63 | 38 | 2.5 | 21.5 | 470 |

| RS7622A1/T2-02Y(L)H-54P0.63 | 54 | 2.5 | 23.5 | 610 |

| RS7622A1/T2-02Y(L)H-74P0.63 | 74 | 2.5 | 25.5 | 780 |

| RS7622A1/T2-02Y(L)H-104P0.63 | 104 | 2.5 | 29.0 | 1020 |

| RS7622A1/T2-02Y(L)H-160P0.63 | 160 | 2.5 | 34.0 | 1498 |

| RS7622A1/T2-02Y(L)H-228P0.63 | 228 | 2.5 | 39.0 | 1993 |

| RS7622A1/T2-02Y(L)H-308P0.63 | 308 | 2.5 | 43.5 | 2670 |

| 0.9mm Conductor, 1.5mm Insulated Wire | ||||

| RS7622A1/T2-02Y(L)H-8P0.9 | 8 | 2.5 | 17.5 | 280 |

| RS7622A1/T2-02Y(L)H-14P0.9 | 14 | 2.5 | 20.0 | 380 |

| RS7622A1/T2-02Y(L)H-20P0.9 | 20 | 2.5 | 22.5 | 500 |

| RS7622A1/T2-02Y(L)H-28P0.9 | 28 | 2.5 | 24.5 | 630 |

| RS7622A1/T2-02Y(L)H-38P0.9 | 38 | 2.5 | 25.5 | 790 |

| RS7622A1/T2-02Y(L)H-54P0.9 | 54 | 2.5 | 29.0 | 1060 |

| RS7622A1/T2-02Y(L)H-74P0.9 | 74 | 2.5 | 32.5 | 1370 |

| RS7622A1/T2-02Y(L)H-108P0.9 | 108 | 2.5 | 37.5 | 1830 |

G7622 A1 Type 1 Cables

| Cable Code | No. of pairs | Minimum Sheath Thickness mm |

Nominal Overall Diameter mm |

Nominal Weight kg/km |

|

| Inner | Outer | ||||

| 0.63mm Conductor, 1.0mm Insulated Wire | |||||

| RS7622A1/T1-02Y(L)HY-8P0.63 | 8 | 2.5 | 3.0 | 20.5 | 330 |

| RS7622A1/T1-02Y(L)HY-14P0.63 | 14 | 2.5 | 3.0 | 22.0 | 390 |

| RS7622A1/T1-02Y(L)HY-20P0.63 | 20 | 2.5 | 3.0 | 23.5 | 480 |

| RS7622A1/T1-02Y(L)HY-28P0.63 | 28 | 2.5 | 3.0 | 25.5 | 560 |

| RS7622A1/T1-02Y(L)HY-38P0.63 | 38 | 2.5 | 3.0 | 27.5 | 660 |

| RS7622A1/T1-02Y(L)HY-54P0.63 | 54 | 2.5 | 3.0 | 29.5 | 830 |

| RS7622A1/T1-02Y(L)HY-74P0.63 | 74 | 2.5 | 3.0 | 31.5 | 1010 |

| RS7622A1/T1-02Y(L)HY-104P0.63 | 104 | 2.5 | 3.0 | 35.0 | 1290 |

| 0.9mm Conductor, 1.5mm Insulated Wire | |||||

| RS7622A1/T1-02Y(L)HY-8P0.9 | 8 | 2.5 | 3.0 | 23.5 | 440 |

| RS7622A1/T1-02Y(L)HY-14P0.9 | 14 | 2.5 | 3.0 | 26.0 | 550 |

| RS7622A1/T1-02Y(L)HY-20P0.9 | 20 | 2.5 | 3.0 | 28.5 | 700 |

| RS7622A1/T1-02Y(L)HY-28P0.9 | 28 | 2.5 | 3.0 | 30.5 | 840 |

| RS7622A1/T1-02Y(L)HY-38P0.9 | 38 | 2.5 | 3.0 | 31.5 | 1020 |

| RS7622A1/T1-02Y(L)HY-54P0.9 | 54 | 2.5 | 3.0 | 35.0 | 1310 |

| RS7622A1/T1-02Y(L)HY-74P0.9 | 74 | 2.5 | 3.0 | 38.5 | 1650 |

| RS7622A1/T1-02Y(L)HY-104P0.9 | 104 | 2.5 | 3.0 | 43.5 | 2160 |

Armoured G7622 A1 Type 2 Cables

| Cable Code | No. of pairs | Minimum Sheath Thickness mm |

Nominal Overall Diameter mm |

Nominal Weight kg/km |

|

| Inner | Outer | ||||

| 0.63mm Conductor, 1.0mm Insulated Wire | |||||

| RS7622A1/T2-02Y(L)H(SR)H-8P0.63 | 8 | 1.2 | 2.5 | 18.2 | 430 |

| RS7622A1/T2-02Y(L)H(SR)H-14P0.63 | 14 | 1.2 | 2.5 | 19.0 | 500 |

| RS7622A1/T2-02Y(L)H(SR)H-20P0.63 | 20 | 1.2 | 2.5 | 21.2 | 600 |

| RS7622A1/T2-02Y(L)H(SR)H-28P0.63 | 28 | 1.2 | 2.5 | 22.6 | 690 |

| RS7622A1/T2-02Y(L)H(SR)H-38P0.63 | 38 | 1.2 | 2.5 | 24.2 | 810 |

| RS7622A1/T2-02Y(L)H(SR)H-54P0.63 | 54 | 1.2 | 2.5 | 26.7 | 980 |

| RS7622A1/T2-02Y(L)H(SR)H-74P0.63 | 74 | 1.2 | 2.5 | 29.2 | 1190 |

| RS7622A1/T2-02Y(L)H(SR)H-104P0.63 | 104 | 1.2 | 2.5 | 32.6 | 1480 |

|

|

|

|

Mineral Oil Resistant |

Rated voltage |

Buried in Ciround |

Laid In Ducts |

PVC Sheath |

|

LSZH Sheath |

|